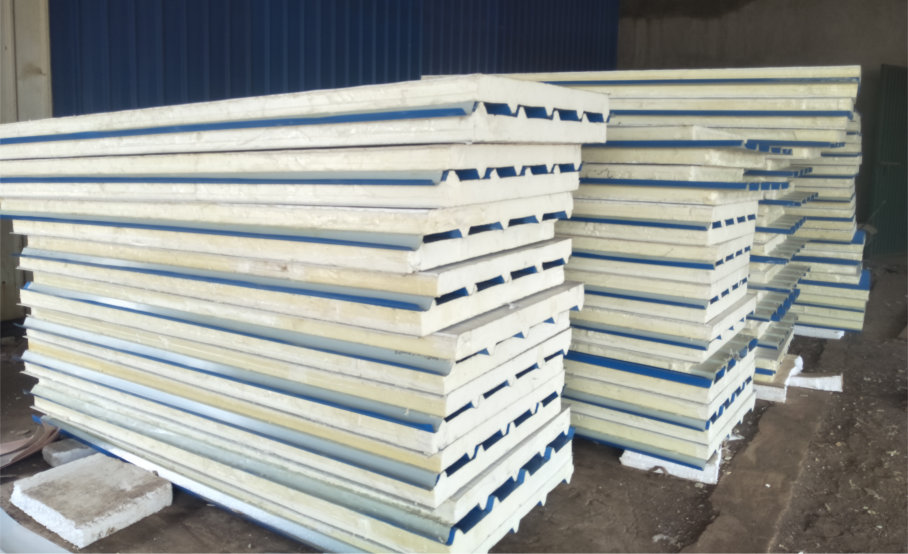

PREMIUM & HIGH QUALITY SANDWICH PANELS MANUFACTURER

Tek Engineering is a leading manufacturer of PU Sandwich Panels in Pakistan. As one of the country's largest producers, we specialize in crafting high-quality Sandwich Panels with both EPS (Expanded Polystyrene) and PU (Polyurethane) insulation options.

Sandwich Panels for All Types of Pre-Engineered Steel Buildings.

Sandwich Panels Best for Commercial and industrial Buildings

Sandwich panels are high-performance, factory-engineered units, designed as a single modular piece. These panels consist of two durable metal faces that enclose highly efficient insulating materials, such as Polyurethane (PU) or Polystyrene (EPS). Known for their versatility, sandwich panels are used in a variety of applications, including residential, commercial, and industrial buildings.

Tek Engineering Services manufactures a broad range of sandwich panels that offer exceptional performance. These panels are waterproof, tamper-proof, corrosion-resistant, and durable, making them ideal for various building needs. Our product offerings include Polyurethane (PU) and Expanded Polystyrene (EPS) sandwich panels, cold storage rooms, modular homes, portable cabins, pre-engineered buildings in Pakistan.

Modern Technology in Buildings

Building Durability Reducing Costs

Experienced Engineers

Steel Construction Long Future

Sandwich Panels: A Key Material for Lightweight, High-Strength Structures

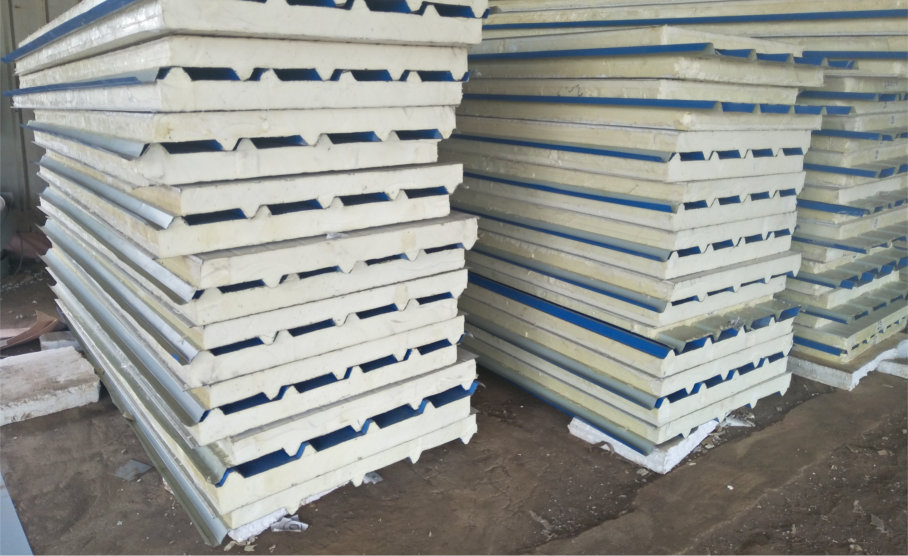

A sandwich panel is a versatile structural material made of three distinct layers. The core is a low-density material such as PIR (Polyisocyanurate), mineral wool, or XPS (extruded polystyrene), and each side of the core is bonded to a thin, durable skin layer. This innovative combination of materials provides an ideal solution for applications requiring both high strength and low weight.

In essence, a sandwich panel functions similarly to the classic I-beam, a widely used structural component in construction. The outer face sheets, made of strong and thin materials, bear the brunt of the in-plane and lateral bending loads, akin to the flanges of an I-beam. Meanwhile, the core material primarily absorbs the shear loads, comparable to the web of the I-beam. The core layer is typically thick and soft but lightweight, while the face sheets are thin and strong. This design not only increases the overall thickness of the panel, improving its bending stiffness, but also keeps the overall weight relatively low.

By using lightweight, insulating materials as the core and strong, durable face sheets, sandwich panels are capable of achieving superior structural properties. This makes them especially valuable for a wide range of industries, offering solutions that combine enhanced strength with minimized weight and energy efficiency.

Lightweight, Durable, and Insulating Solutions for Modern Steel Construction

Sandwich panels are used in numerous sectors where the demand for high structural performance combined with minimal weight is critical. These panels are widely employed in the construction of various buildings and systems.

Cold Storage Warehouses Facilities (Warehouses and Cold Rooms)

Cold storage units, such as refrigerated warehouses and cold rooms, benefit from the thermal insulation properties of sandwich panels. The low-density core material, combined with the durable exterior, ensures temperature control and energy efficiency.

Sandwich Panels Are the Ideal Choice for Food Processing Plant Buildings

Sandwich panels are an ideal choice for constructing food processing plants, as they offer superior temperature control and hygiene. These panels help maintain stable internal temperatures, which is crucial for food safety, while also being highly resistant to corrosion and other environmental challenges. Their durability and efficiency make them an excellent option for ensuring a controlled and sanitary environment in food production facilities.

Lightweight Buildings Warehouses

Sandwich panels are ideal for warehouses, providing a lightweight yet durable option for large-scale structures. Additionally, these sandwich panels offer exceptional thermal insulation, which helps regulate indoor temperatures, making the warehouse environment more energy-efficient and cost-effective.

Refrigerated Vehicle Solutions

Transport vehicles requiring temperature regulation, such as refrigerated trucks or delivery vans, often rely on sandwich panels to ensure optimal conditions throughout transit. We are manufacturing of both refrigerated and non-refrigerated vehicles, utilizing sandwich panels for temperature control.

Partition Walls

Within large facilities, sandwich panels are often used as partition walls. These walls are easy to install, lightweight, and offer excellent insulation properties, making them ideal for dividing spaces within a building. Best for Modular homes, temporary office and school and college room wall partition.

Agricultural Project Storage Halls

In agricultural settings, storage halls built with sandwich panels offer superior durability, insulating properties, and the ability to withstand environmental conditions, making them ideal for storing produce or equipment.

Fire-Resistant Rooms

Certain areas, especially in chemical processing facilities or laboratories, require fire-resistant rooms to ensure safety. Sandwich panels with fire-resistant cores are an excellent choice for constructing these specialized rooms, providing both protection and structural integrity.

Chemical Processing Facilities

Chemical plants often have stringent safety standards and need materials that can handle extreme conditions. Sandwich panels to meet fire and chemical resistance requirements, making them suitable for these types of environments.

Exhibitions and Shopping Malls

Exhibition halls and shopping malls utilize sandwich panels for their ease of construction and aesthetic flexibility. These panels allow for the creation of large, open spaces with optimal temperature control and sound insulation properties.

Sports and Fitness Complexes

Sports facilities, such as gyms and fitness complexes, benefit from the insulation properties of sandwich panels, ensuring temperature regulation and acoustic control within the facility.

Sports Stadiums

Stadiums require large structural elements that are both lightweight and durable. Sandwich panels are often used for the construction of walls, roofs, and partitions in stadiums, providing optimal performance and efficiency.

Prefabricated Classrooms and Offices

The flexibility and quick installation of sandwich panels make them an excellent choice for modular construction, such as prefabricated classrooms and office buildings. These structures offer a cost-effective and energy-efficient solution for educational and commercial spaces.